AN INTRODUCTION TO NAPIER’S PRODUCTS

D Napier & Son Limited produced a very diverse range of products over the 150 years of the Company’s existence. Always a precision engineering company Napiers products tended to follow the ‘high end’ requirements of the day.

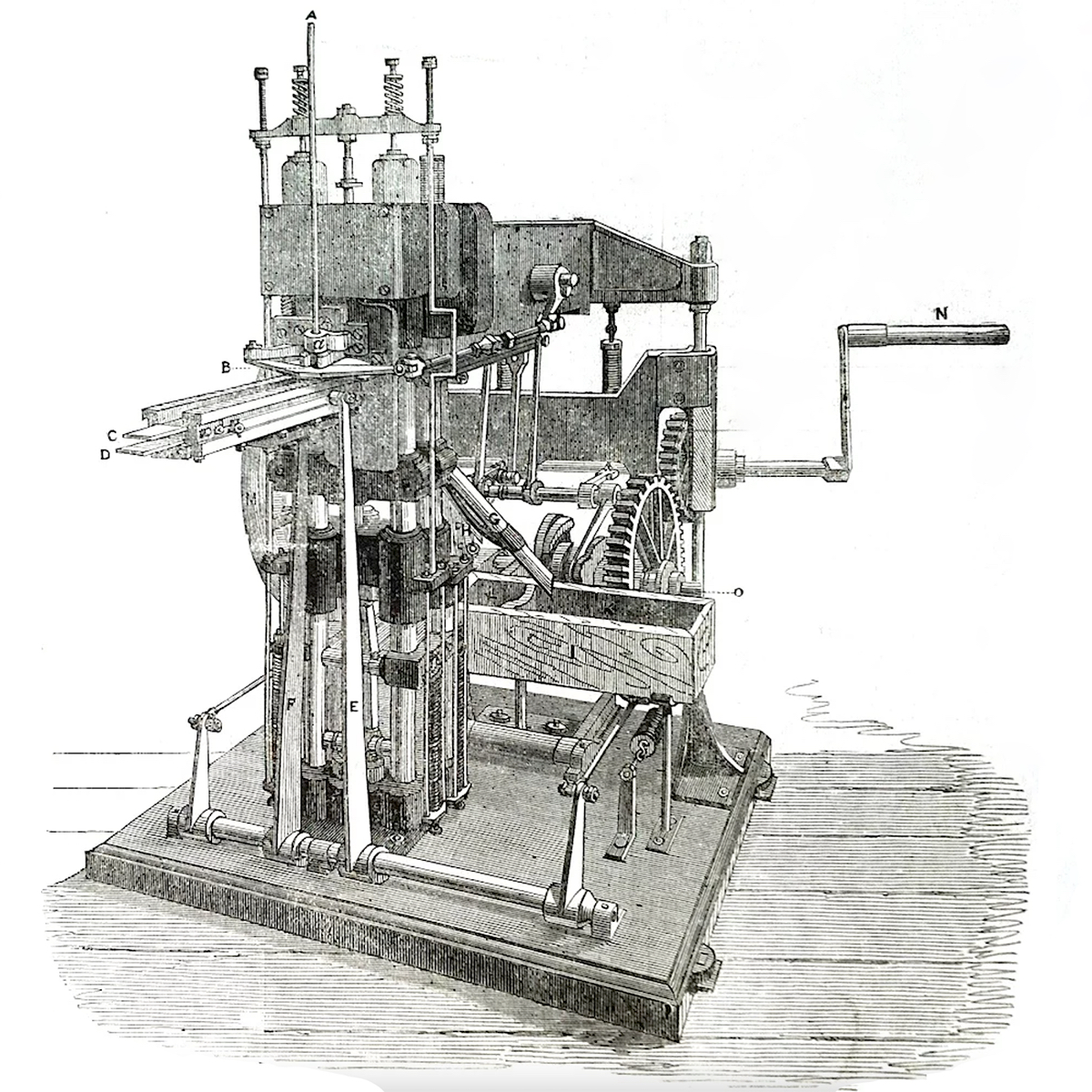

Before the 20th Century the majority of the Company’s products were manufactured for applications where exact tolerances were required. Initially these were printing presses supplied to the industry around the original Napier Soho workshops. As David Napier’s reputation increased he was approached to produce a range of specialist precision manufactured machinery. These included coin and bullion balances for the Royal Mint, the first accurate stamp perforating machines for Somerset House, and the first accurate cold bullet press for the Woolwich Arsenal. David Napier’s reputation for inventiveness and quality meant that he won many government contracts. This was something that the Company followed for most of its existence.

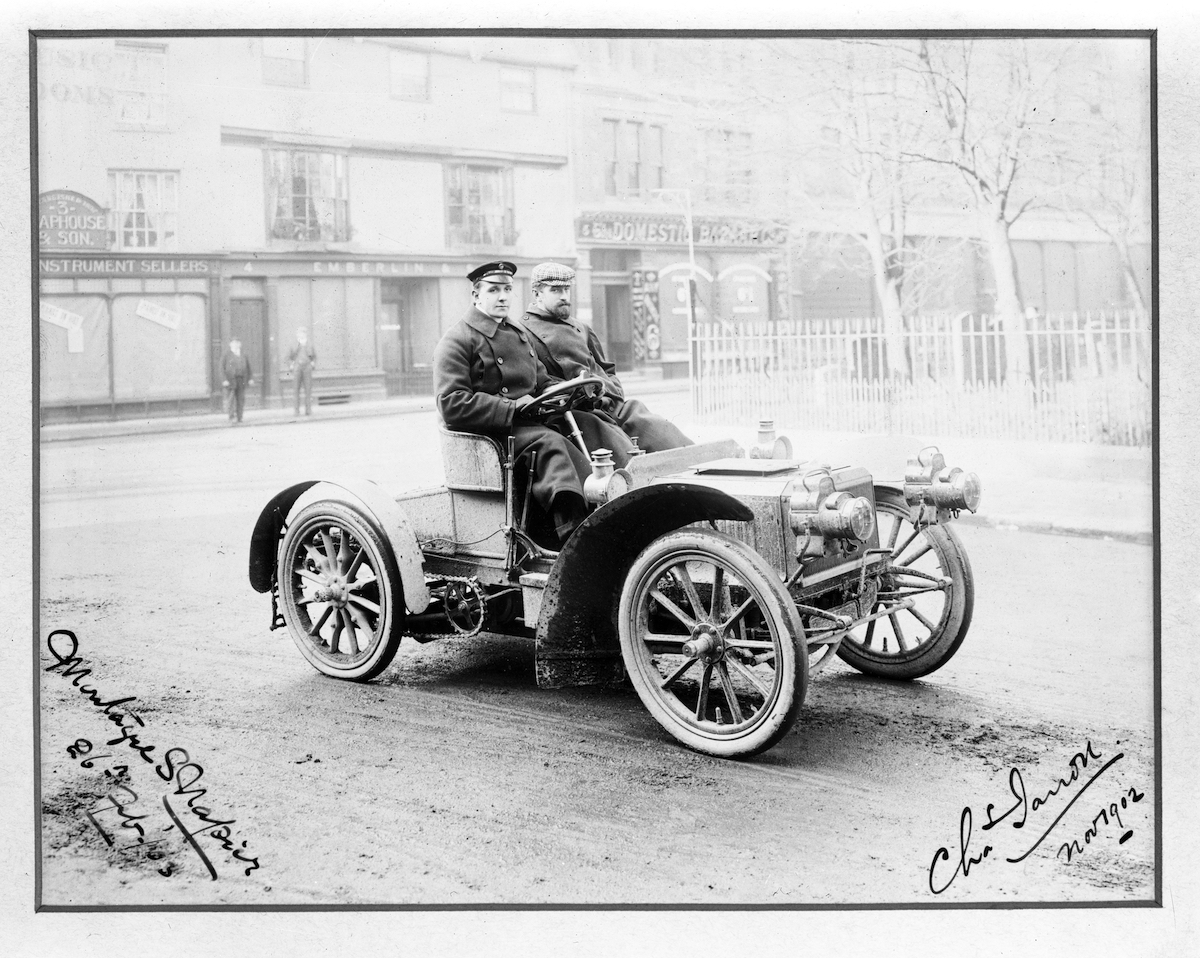

When Montague Napier took over the business his attention turned to vehicle production. To this end he was encouraged and ably assisted by his very close friend Selwyn Francis Edge who promoted and sold Napier cars on an exclusive basis. This website includes a comprehensive section covering the Napier Marque originally written by the late Derek Grossmark, VCC registrar of Napier vehicles. It was Derek who rescued and carefully preserved the Napier Car archives from the Company in 1961/2. It is fitting that this section of the website is dedicated to Derek.

Napier Aero Engines

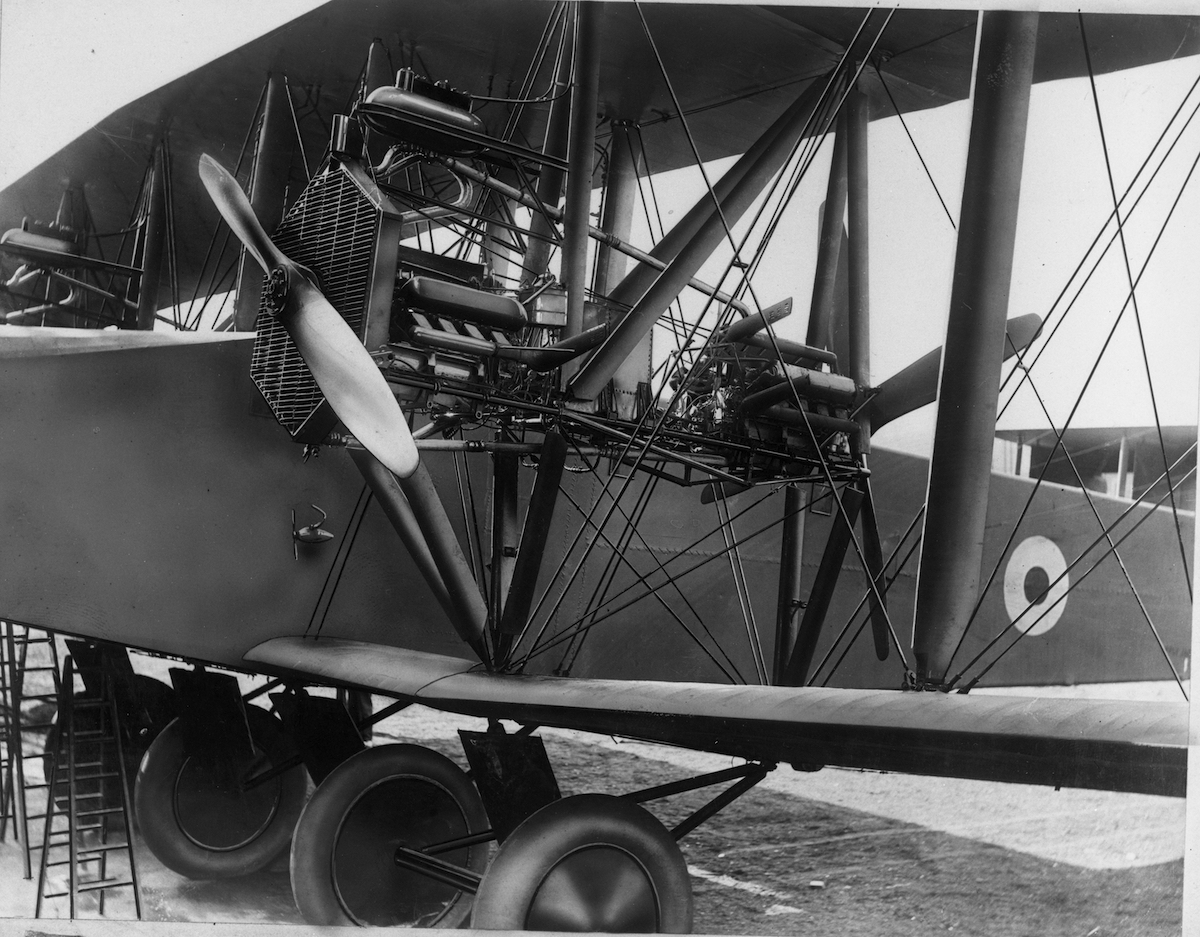

During the First World War the Company became involved producing aircraft and later aero engines for the war effort. Montague Napier considered these RAF3A and Sunbeam Arab aircraft engines to be inferior products. After the Ministry refused to sanction a new engine design Montague self financed the development of what became the Lion engine. This was used in many aircraft between the wars and also fitted in many air, land and water record breakers dominating the world record scene throughout the entire first half of the 20th Century.

Engine development continued between the wars and climaxed during WWII with the famous Sabre engine fitted in the Hawker Typhoon and Tempest aircraft and becoming the most powerful piston aero engine produced in that period. Post-war engine development moved towards gas turbine (Naiad & Gazelle) and turbo-prop (Eland) not to mention the Napier Nomad compound engine – the most fuel efficient aero engine developed up to that time. Napier’s Luton Flight Development Establishment was also heavily involved in developing rocket motors including the Napier Scorpion which, in 1957, boosted a Canberra Bomber to an altitude of over 57,000 feet and another world record for Napier.

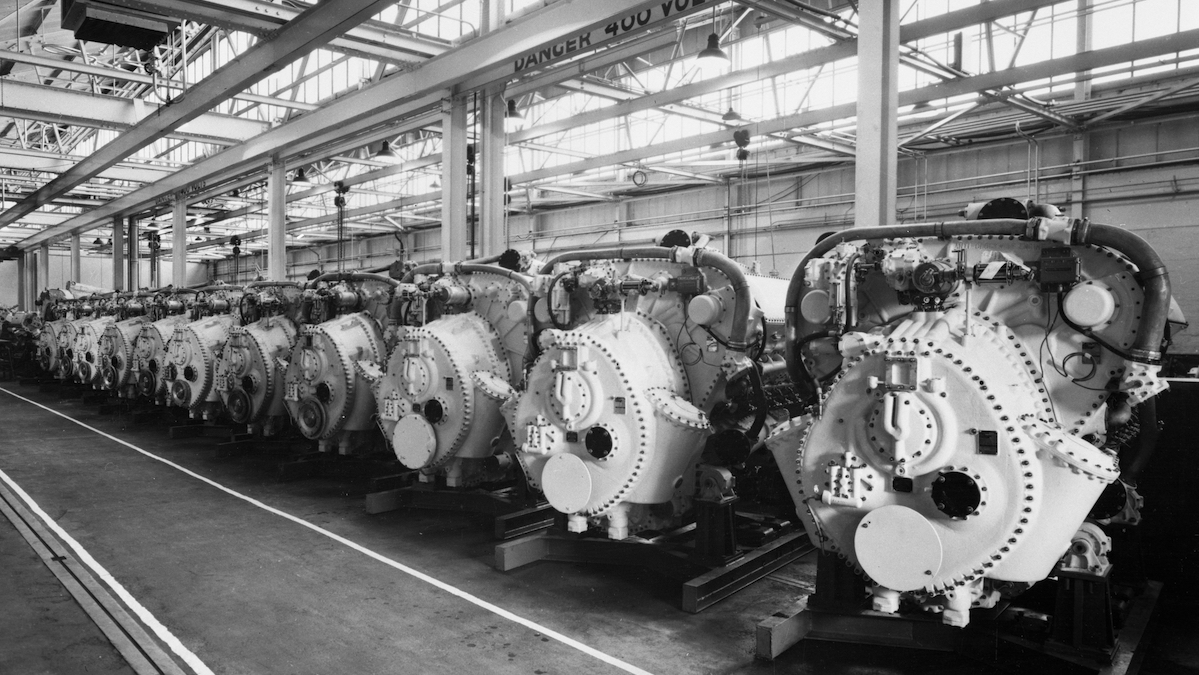

The Napier Lion engine was used by Hubert Scott-Paine and used by his British Powerboat Company. The marinised engine was named the Napier SeaLion. In 1943 the Royal Navy identified a requirement for a powerful 2,500 BHP marine diesel engine. In 1946 D Napier & Son started to design and build its famous Deltic marine engine which also saw use in rail and other land based applictions.

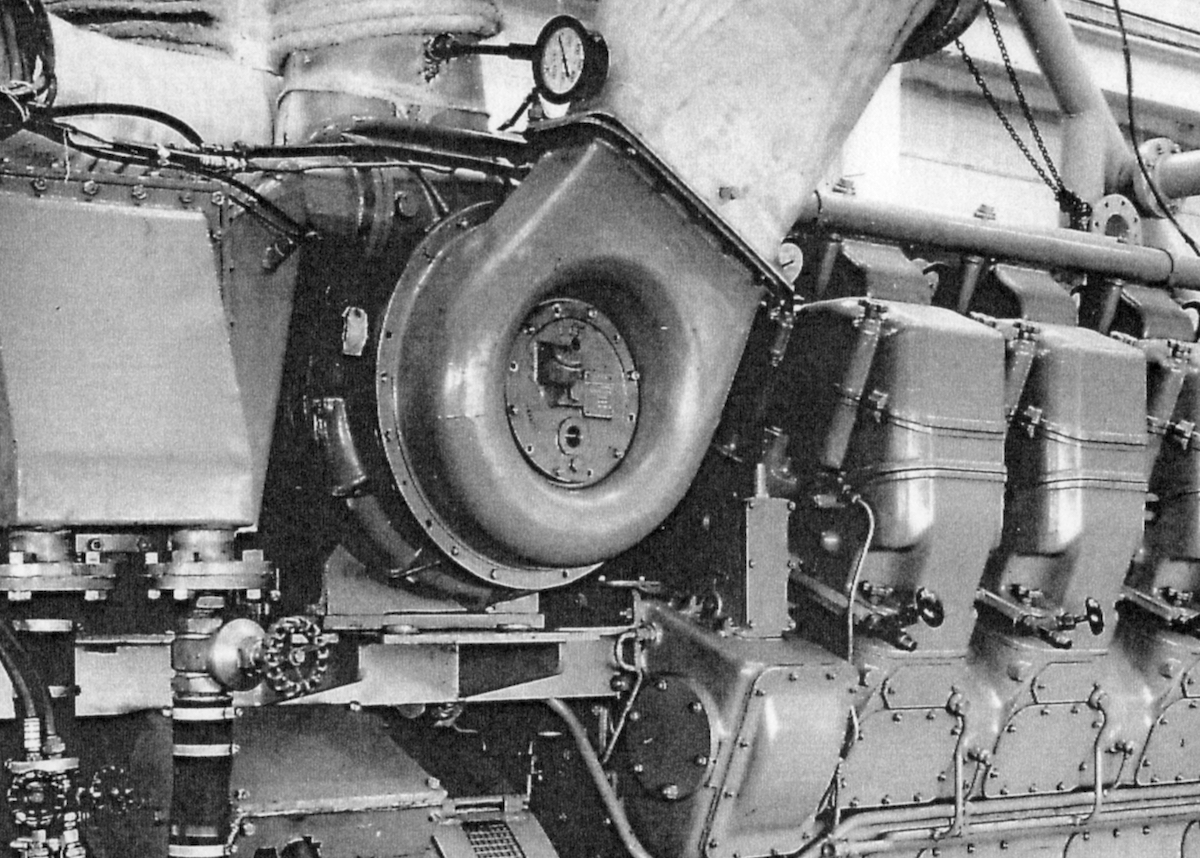

In 1942 D Napier & Son was absorbed into the English Electric Group of Companies. Amongst its diverse activities it manufactured large diesel engines. In order to increase their power it was found that fitting turbochargers made a huge difference. Drawing from experience in turbine technology Napiers developed a new business producing large turbo-blowers / turbochargers.

Another product of Luton’s Flight Development Establishment was Spraymat de-icing equipment. This revolutionary product was used to prevent ice build-up on leading edges of aircraft wings, intakes, etc.

D. Napier & Son also produced a range of miscellaneous for other divisions of English Electric and external customers. These often drew on the skills that the Company already had. For example its precision casting department manufactured turbine blades for the new gas turbine industry. It was involved in castings for special use such as the front landing gear for the Avro Vulcan bomber as well as gas bearings and gas seals for use in power stations.